one、definition

Hot rolled steel plate refers to the steel plate produced through the hot rolling process���。Hot rolling refers to the rolling process carried out above the recrystallization temperature of metals�����。For steel�,The recrystallization temperature is usually at800℃ - 900℃about。During the hot rolling process���,Steel is rolled into the required thickness and shape at high temperatures��。

two�、Production process

The production process of hot-rolled steel plates mainly includes the following steps:

raw material preparation

Molten iron and scrap steel:Molten iron mainly comes from ironmaking blast furnaces�����,Scrap steel is used to adjust the composition and reduce costs�。

external refining:Through external refining technology,Like vacuum treatment���、Powder coating treatment, etc�����,F(xiàn)urther adjust the composition and purity of the molten steel�����。

heating

steel billet(Like a square billet����、rectangular billet)Sent into the heating furnace and heated until1100℃ - 1300℃���。The purpose of heating is to bring the steel billet to the appropriate temperature����,In order to have good plasticity and low deformation resistance in the subsequent rolling process��。

roughing

The heated steel billet enters the roughing mill���,After multiple passes of rolling�����,Gradually reduce the thickness����,Simultaneously adjust the width�。The main purpose of rough rolling is to roll the steel billet into an intermediate billet that is close to the thickness of the finished product。

finish rolling

The intermediate billet enters the precision rolling mill,After multiple rounds of precision rolling�,F(xiàn)inally achieving the thickness of the finished product。During the precision rolling process�,The precision of rolling rolls and the control of rolling process parameters are crucial for the dimensional accuracy and surface quality of steel plates。

cooling

The precision rolled steel plate enters the cooling bed for cooling���。There are natural cooling methods for cooling��、forced air cooling�����、Water cooling, etc�����,Different cooling methods can affect the microstructure and properties of steel plates�����。

straightening

The cooled steel plate may have some bending or deformation�����,Need to be straightened by a straightening machine�����,Make it meet the flatness requirements��。

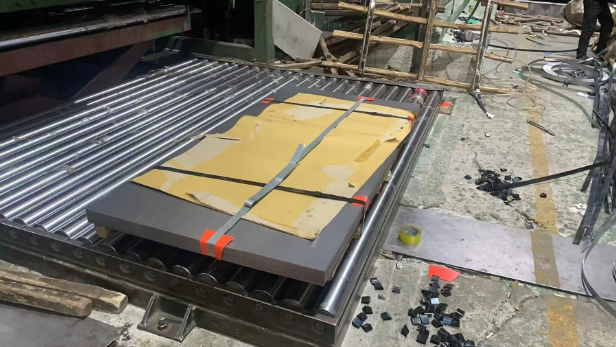

Inspection and Packaging

Regarding the dimensions of the steel plate���、SURFACE QUALITY、Testing of mechanical properties, etc�,Qualified products are packaged and stored in the warehouse。

three����、classification

Hot rolled steel plates can be classified according to different standards:

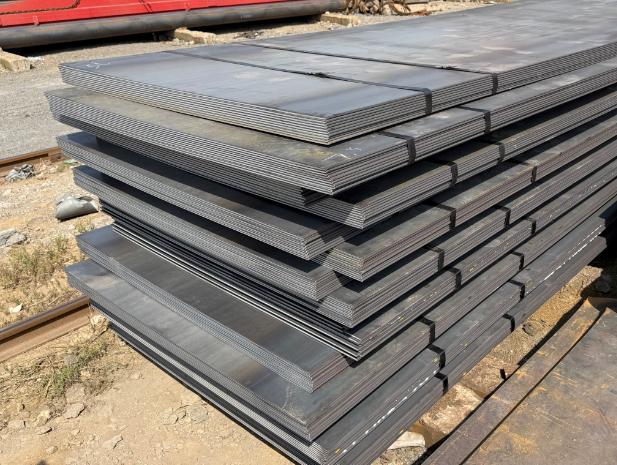

Classified by thickness

thick plate:thickness≥4.5mmThe steel plate。

sheet:thickness<4.5mmThe steel plate���。

Function

Ordinary structural steel:in compliance withQ235�����、Q355class���,Used for general building structures and mechanical manufacturing。

Low alloy high-strength steel:in compliance withQ460��、Q550class,Has high strength and good toughness����,Used for manufacturing bridges、building structure���、Heavy machinery, etc���。

Special steel:Such as shipbuilding steel、automobile steel��、Boiler steel, etc����,Steel designed for specific purposes,Has special performance requirements�����。

Classified by surface quality

normal precision:Slight scratches are allowed on the surface����、Defects such as pockmarks。

high-precision:High surface quality requirements�����,No obvious defects。

four�����、Performance characteristics

mechanical property

strength:Hot rolled steel plates have high strength�,Capable of withstanding large loads。

resilience:Has good resilience�,Capable of adapting to complex processing and usage environments。

hardness:Moderate hardness���,Easy to process and weld。

processability

solderability:Hot rolled steel plates have good welding performance����,Suitable for various welding processes。

Formability:Can be stamped��、Processing into complex shapes using bending and other techniques���。

corrosion resistance

Hot rolled steel plates themselves have poor corrosion resistance����,Usually requires surface treatment(Like galvanizing、Painting, etc)To improve corrosion resistance���。

five��、application area

Hot rolled steel plate due to its excellent mechanical and processing properties�����,Widely used in various fields:

Construction field

Used for building structures��、bridge��、Beams, columns, etc. of high-rise buildings����。

Machinery manufacturing

Used for manufacturing mechanical components���、Heavy machinery structural components, etc�。

automobile making

Used for automotive body frames����、Engine components, etc。

Shipbuilding

Used for manufacturing ship structures�����、Deck, etc。

energy sector

Used for manufacturing boilers��、Pressure vessels, etc���。

six�、advantages and disadvantages

advantage

High production efficiency:High production efficiency of hot rolling process���,Suitable for large-scale production��。

Low cost:Compared to cold-rolled steel plates���,The production cost of hot-rolled steel plates is relatively low���。

Excellent performance:Has high strength and good toughness����。

disadvantage

Low dimensional accuracy:Due to temperature changes and other factors during the hot rolling process�,Relatively low dimensional accuracy。

Poor surface quality:There may be oxide scale on the surface���、Scratches and other defects��,F(xiàn)urther processing is required���。

Poor corrosion resistance:Surface treatment is required to improve corrosion resistance�����。

seven�����、development trend

With the continuous advancement of technology��,The production process of hot-rolled steel plates is also constantly developing and improving�。The future development trends include:

Increase productivity:Through automation and intelligent technology�����,F(xiàn)urther improve production efficiency����。

Improve product quality:Developing high-performance hot-rolled steel plates,Meet the needs of high-end manufacturing industry。

Green and environmentally friendly:Adopting environmentally friendly production processes���,Reduce energy consumption and environmental pollution���。

Hot rolled steel plate as an important basic material,Has an irreplaceable position in industrial production���。By continuously optimizing production processes and improving product quality����,Hot rolled steel plates will play a greater role in more fields����。