Knowledge of hot-dip galvanized steel sheet

one����、definition

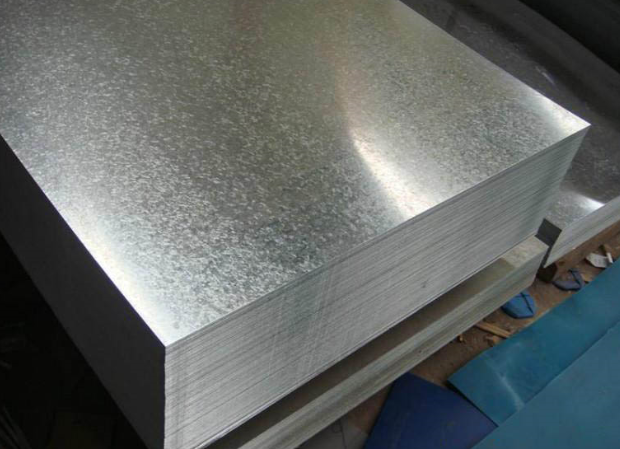

Hot dip galvanized steel sheet refers to the process of hot-dip galvanizing�,Steel with a zinc protective layer formed on the surface of the steel plate。This process not only improves the corrosion resistance of steel plates����,It also extended its service life。Hot dip galvanized steel sheet is widely used in construction�、automobile making、Multiple fields such as home appliances�����。

two�、Production process

The production of hot-dip galvanized steel sheet mainly adopts continuous hot-dip galvanizing process,The core steps are as follows:

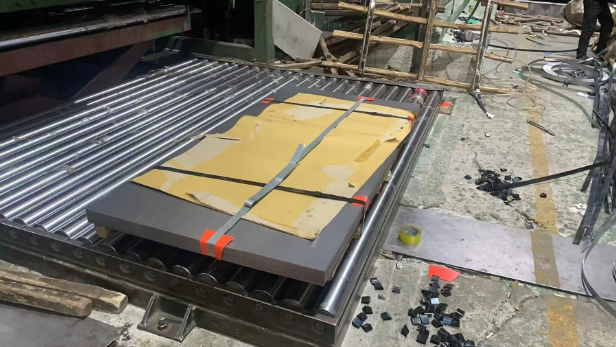

Uncoiling and welding:After unwinding the steel coil���,Weld the tail of the forward strip steel to the head of the backward strip steel,Ensure continuous production of the unit。

Degreasing cleaning:By spraying�����、scrub�、Electrolytic cleaning and other methods to remove grease and iron powder from the surface of the strip steel,Ensure coating adhesion and surface quality���。

annealing:Recrystallize and anneal the strip steel���,To achieve good mechanical performance,And optimize the coating performance by controlling the furnace atmosphere�。

CGL:Immerse the pre treated strip steel into a temperature of450℃ - 470℃Galvanizing in molten zinc solution。

Air knife controls the thickness of the zinc layer:Spray gas onto the surface of the strip steel through an air knife(Like air or nitrogen)�����,Control the thickness of the zinc layer����。

Cooling and passivation treatment:Galvanized strip steel after cooling,Usually, passivation treatment is carried out in chromic acid or phosphoric acid solution���,F(xiàn)orming a protective film��,Improve anti-corrosion performance�。

Correction and Inspection:Correct the galvanized strip steel,Restore its flatness���,And conduct quality inspection�。

three��、Performance characteristics

corrosion resistance:The zinc layer can effectively isolate the steel plate from the external environment�����,prevent corrosion���,Its corrosion resistance is usually the same as that of ordinary steel25times��。

Strong adhesion:The zinc layer is firmly bonded to the steel plate�,Not easy to fall off��。

Good processing performance:Has good formability and weldability����,Suitable for various processing techniques。

anodic sacrifice protection:Zinc is more prone to oxidation than iron��,Even if scratches appear on the surface of the coating���,Zinc will also preferentially corrode��,Thus protecting the substrate���。

four、application area

construction industry:Used for roofs�、wall、Structural components such as drainage ditches����,Provide long-term rust prevention protection。

Automobile industry:Used for vehicle body components�����、Chassis, etc�,Enhance the durability and safety of vehicles。

Home appliance manufacturing:Used for refrigerators���、washing machine����、Air conditioning and other enclosures,Enhance aesthetics and durability����。

five、Common problems and solutions

Zinc layer peeling off:Possible surface oxidation�����、Cold rolling emulsion is unclean�����、Caused by low aluminum content in zinc pots����。

White rust and black spots:Usually due to the surface not being coated with oil、Due to residual moisture or improper storage��,Attention should be paid to moisture prevention and timely handling��。

Hot dip galvanized steel sheet due to its excellent corrosion resistance and processing performance�����,Plays an important role in modern industry。By optimizing production processes�,It can further enhance its performance and application scope。